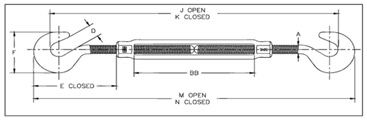

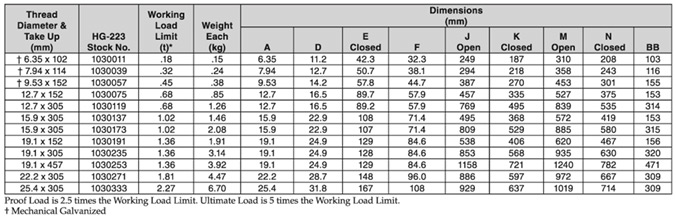

HOOK& HOOK TURNBUCKLES

• End fittings are Quenched and tempered or normalized, bodies heat treated by normalizing.

• Hot dip galvanized steel.

• Hooks are forged with a greater cross sectional area that results in a stronger hook with better fatigue properties.

• Meets or exceed all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these turnbuckle meet other critical performance requirements including fatigue life. Impact properties and material traceability, not addressed by ASME B30.26

HOOK& EYE TURNBUCKLES

• End fittings are Quenched and tempered or normalized, bodies heat treated by normalizing.

• Hot dip galvanized steel.

• Turnbuckle eyes are forged elongated, by design to maximize easy attachment in system and minimize stress in the eye .For turnbuckles sizes ¼”through 1”,a shackle one size smaller can be reeved through eye.

• Turnbuckle hook are forged with a grater cross sectional area that result in a stronger hook with better fatigue properties.

• Meet or exceed all requirement of ASME B30.26 including identification, ductility, design factor, proof of load and temperature requirements. Importantly, these turnbuckle meet other critical performance requirements. Importantly ,these turnbuckles meet other critical performance requirements including fatigue life, Impact properties and material traceability, not addressed by ASME B30.26

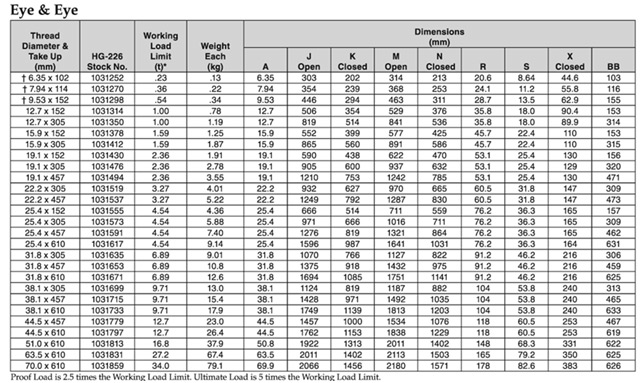

EYE & EYE TURNBUCKLE

HG-226

• End fittings are Quenched and tempered or normalized ,bodies heat treated by normalizing .

• Hot dip galvanized steel.

• Turnbuckle eyes are forged elongated ,by design ,to maximize easy attachment in system and minimize stress in the eye .For turnbuckle size 6mm through 64mm,a shackle one size smaller can be reeved through eye .

• Modified UNJ thread on end fitting for improved fatigue properties .Body has UNC threads.

• Meet or exceed all requirements of ASME B30.26 including identification ,ductility ,design factor ,proof load and temperature requirements. Importantly, these turnbuckles meet other critical performance requirements including fatigue life ,impact properties and material traceability ,not addressed by ASME B30.26.

• Turn buckles recommended for straight or in –line pull only

JAW & JAW TURNBUCKLE

HG-228

• End fittings are Quenched and tempered or normalized, bodies heat treated by normalizing.

• Hot dip galvanized steel.

• TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN –LINE PULLY ONLY.

• Forged jaw ends are fitted with bolt and nuts for 6mm through 16mm,and pins and cotters on 19mm trough 70mmsizes.

• Modified UNJ thread on end fitting for improved fatigue properties.

• Body has UNC threads.

• Meet or exceeds all requirements of ASME B30.26 including identification ,ductility ,design factor ,proof load and temperature requirements .Importantly ,these turnbuckle meet other critical performance requirements including fatigue life ,impact properties and material traceability, not addressed by ASME B30.26.

• Fatigue rated

Meet the performance requirements

of federal specification FF-T-791b,

type 1,form 1-class 7,and ASTM F-1145,

except for those provisions required of the contractor .