Forged Wire Rope Clip

APPLICATION AND INFORMATION

• Each base has a Product Identification Code (PIC) for material traceability, the name Crosby or CG, and a size forged into it.

• Based on the catalog breaking strength of wire rope, Crosby wire rope clip have an efficiency rating of 80% for 3-4mm to 22mm sizes, and 90% for sizes 24-26mm through 90mm.

• Entire Clip-Galvanized to resist corrosive and rusting action.

• Sizes 1/8” through 2-1/2” and 3” (3mm through 65mm and 75-78mm) have forged bases.

• All clips are individually bagged or tagged with proper application instructions and warning information.

• Clip sizes up through 1-1/2” (38mm) have rolled threads.

• Meets or exceed all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these wire rope clips meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

Solid Wire Rope Thimble

• Cast Ductile Iron.

• Fits pin for open wire rope socket, boom pendant clevis and wedge socket.

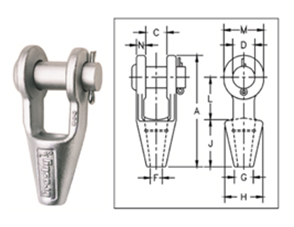

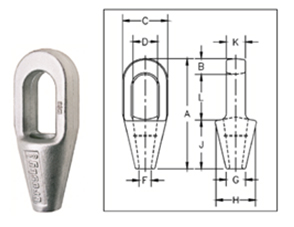

Open & Closed Spelter Socket

Forged steel sockets through 38mm, cast alloy steel 40mm through 102mm.

Spelter socket terminations have an efficiency rating of 100%, based on the catalog strength of wire rope. Ratings are based on the recommend use with 6×7, 6×19, or 6×36, IPS or XIP (EIP), XXIP (EEIP), RRL, FC, or IWRC wire rope. Strand constructed with minimal number of wires (e.g. 1×7) requires special consideration that socket basket be five (5) times the strand diameter or fifty (50) times the wire diameter, whichever is the greater.

G416 / S-416

G416 / S-416  G417 / S-417

G417 / S-417G416 / S-416

Wedge Sockets & Steel Sleeves

APPLICATION AND INFORMATION

Wedge socket terminations have an efficiency rating of 80% based on the catalog strength of XXIP wire rope.Meets or exceed all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these sockets meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.Type approval and certification in accordance with ABS 2006 steel Vessel Rules 1-1-17.7, and ABS Guide fo r Certification of Cranes.Basket is cast steel and individually magnetic particle inspected.Pin diameter and jaw opening allows wedge and socket to be used in conjunction with closed swage and spelter sockets.Secures the tail or “dead end” of the wire rope to the wedge, thus eliminates the loss or “punch out” of the wedge.

Eliminates the need for an extra piece of rope, and is easily installed.The TERMINATORᵀᴹ wedge eliminates the potential breaking off of the tail due to fatigue.The tail, which is secured by the base of the clip and the wedge, is left undeformed and available for reuse.

Incorporated Crosby’s patented QUICK CHECK® “Go” and “No-Go” feature cast into the wedge. The

proper size is determined when the following criteria are met:

1) The wire rope should pass thru the “Go” hole in the wedge.

2) The wire rope should not pass thru the “No-Go” hole in the wedge.

Utilizes standard Crosby Red-U-Bolt® wire rope clip.The 9-10mm through 28mm standard S-421 wedge socket can be retrofitted with the new style TERMINATORᵀᴹ wedge.Available with Bolt, Nut, and Cotter Pin. US patent 5,553,360, Canada patent 2,217,004 and foreign equivalents.Meets the performance requirements of EN 13411-6: 2003.

Steel Sleeves

S 505- Cold Tuff- Special processed low carbon steel sleeves using for Flemish eye wire rope splicing.

– Designed for low temperature toughness.

– Resists cracking when swaged. (Equals or exceeds stainless steel sleeves)

– Special processed low carbon steel.

Note: S-505 Standard sleeves are recommended for use with 6×19 or 6×37, IPS or XIP (EIP), XXIP (EEIP), RRL, FC or IWRC wire rope.