Hooks are used in lifting systems as a connection between the load to be lifted and the wire rope or chain slings. There are different types of hooks with their specific designs to suit a particular purpose. Eye hooks and swivel hooks are designed for wire rope or chain.

Note: It is required that the products are regularly inspected and that the inspection should take place in the safety standards. This is required because the products in use may be affected by wear, misuse, overloading etc. with a consequence of deformation and alteration of the material structure. Inspection should take place at least every six months and even more frequently when the hooks are used in severe operating conditions.

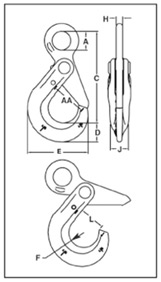

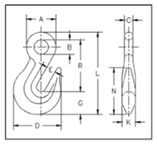

EYE HOOKS (S-320 & S-320N)

ALL Crosby 320 eye hoist hooks incorporate the following features:

• The most complete line of eye hoist hooks.

• Available in carbon steel and alloy steel.

• Designated with a 5:1 Design Factor For (Carbon Steel); 4:1 Design Factor for

(Alloy Steel).

• Eye hooks are load rated.

• Proper design, careful forging and precision controlled quenched and tempering give maximum strength without excessive weight and bulk.

• Every Crosby eye hook has a pre –drilled cam which can be equipped with a latch. Even years after purchase of the original hook, latch assemblies can be added.

• Chemical analysis and tensile tests performed on each PIC to verify chemistry and mechanical properties.

• Type approval and certification in accordance with.ABS 2006 steel vessel rules 1-1-17.7, and ABS guide for certification of cranes.

• Hoist hooks incorporate two types of strategically placed marking forged into the product which address two(2) QUIC-CHECK® Features:

• Deformation indicators and angle indicators.

*Eye Hooks (3/4 TC -22TA), Proof Load Is 2 Times Working Load Limit. Eye Hooks (20 TC – 60TA).All Carbon Hooks –Average Straightening Load (Ultimate Load) is 5 Times Working Load Limit. Alloy Eye Hooks 1 Ton Through 22 Ton –Average Straightening Load (Ultimate Load)is 5 Times Working Load Limit. Alloy Eye Hooks 30 Ton Through 60 Tons –Average Straightening Load (Ultimate Load) Is 4.5 Times Working Load Limit.

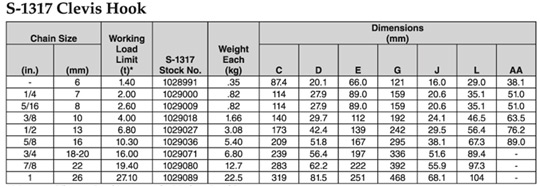

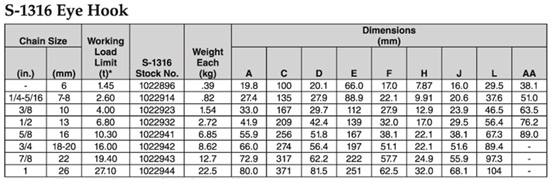

Shur – Loc (Eye & Clevis Self Locking Hook)

SHUR – LOC® Hook Series with Positive Locking Latch

• Forged alloy steel – quenched and tempered

• 25% stronger than grade 80

• Individually proof tested at 2-1/2 times the working load limit with certification.

• Recessed trigger design is flush with the hook body, protecting the trigger from potential damage.

• Easy to operate with enlarged thumb access.

• Meets the performance requirements of en1677-3:2001

• Positive lock latch is self –locking when hook is loaded.

• Eye style is designed with “engineered flat” to connect to s-1325 chain coupler.

• suitable for use with grade 100 and grade 80 chain

• The Shur-loc® hook, if properly installed and locked, can be used for personnel lifting application and meets the intent of Osha rule 1926.1431(g).

• Fatigue rated at 1-1/2 times the working load limit at 20,000 cycles.

• “Look for the platinum colour – Crosby grade 100 alloy products.

*minimum ultimate load is 4 times the working load limit.

Eye Sling Hook – A-327

• Alloy steel – Quenched and Tempered.

• Individually proof tested at 2-1/2 times the working load limit with certification.

• S-4088 Latch Kit Fits Hooks.

*minimum ultimate load is 4 times the working load limit.

A-339 Clevis Sling Hook

Alloy steel – Quenched and Tempered.

• Individually proof tested at 2-1/2 times the working load limit with certification.

• Pin locking requires no special tools.

• S-4088 Latch Fits 19 and 22mm Hooks.

*minimum ultimate load is 4 times the working load limit.

A-329 Eye Foundry Hook

• Alloy steel – Quenched and Tempered.

• Individually proof tested at 2-1/2 times the working load limit with certification.

• Hook can be tip loaded at the reduced working load limit, see below. Operator must ensure the load is retained properly in the hook.

*minimum ultimate load is 4 times the working load limit.

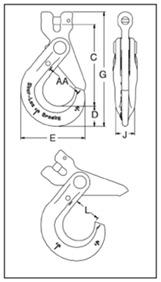

Swivel Hooks (S-322)

• Forged – Quenched and Tempered.

• Swivel hooks are load rated.

• Proper design, careful forging, and precision controlled quench and tempering gives maximum strength without excessive weight and bulk.

• Low profile hook tip designed to utilize Crosby S-4320 OR PL-N Latch Kit. Simply Purchase The Latch Assemblies. Even years after purchase of the original hook, latch assemblies can be added.

• Hoist hooks incorporate markings forged into the product which address two (2)

QUIC-CHECK® features:

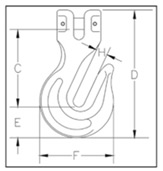

A-328 Eye Grab Hook

• Alloy steel – Quenched and Tempered.

• Individually proof tested at 2-1/2 times the working load limit with certification.

• The use of A-328 eye grab hook will result in 20 percent reduction in chain capacity. When used to hook back to chain leg to form a choker, the angle of the choke must be 120 degrees or greater. When used as a chain shortened, minimize twist of chain and ensure chain is fully engaged in hook.

*minimum ultimate load is 4 times the working load limit. (WLL is there in catalogue)

A-338 Clevis Grab Hook

• Alloy steel – Quenched and Tempered.

• Individually proof tested at 2-1/2 times the working load limit with certification.

• Pin locking requires no special tools.

• The use of A-338 eye grab hook will result in 20 percent reduction in chain capacity. When used to hook back to chain leg to form a choker, the angle of the choke must be 120 degrees or greater. When used as a chain shortened, minimize twist of chain and ensure chain is fully engaged in hook.

*ultimate load is 4 times the working load limit

*ultimate load is 4 times the working load limit

H-330/A-330 Clevis Grab Hooks

• Forged steel – Quenched and Tempered.

• Design factor is 4:1.

• Features quick and easy assembly.

• H- 330 designed for Crosby spectrum 4® chain.

• A-330 Designed for Crosby spectrum 7® chain.

*These A-330 hooks are forged with an “8”designating Grade 80 ,and are suitable for use with Grade 8 chain in over head lifting applications as long as hooks is proof-tested as part of the chain sling assembly or as an individual component per ASME B30.9. We recommend the use of the A-338 which is proof tested and supplied with a proof test certificate.

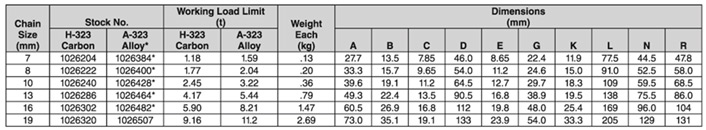

H-323 / A-323 Eye Grab Hooks

• Forged steel – Quenched and Tempered.

• Design factor is 4:1

• H-323 designed for Crosby spectrum 4® chain.

• A-323 designed for Crosby spectrum 7® chain.

*These A-323 hooks are forged with an “8”designating Grade 80 ,and are suitable for use with Grade 8 chain in over head lifting applications as long as hooks is proof-tested as part of the chain sling assembly or as an individual component per ASME B30.9. We recommend the use of the A-328 which is proof tested and supplied with a proof test certificate.

A-350N Sliding Chocker Hook

• New style incorporates throat opening equal to or larger than old style hooks.

• Each product has a product identification code (PIC) for material traceability, along with a working load limit, and the name Crosby or “CG” forged into it.

• All hooks incorporate Crosby’s patented QUIC-CHECK mark to help in determining if throat opening dimension has changed.

• Each hook can be equipped with a Crosby S-4320 heavy duty stamped latch with the high cycle, along life spring.

• Forged alloy steel –Quenched and tempered.

• Design factor of 5 to 1

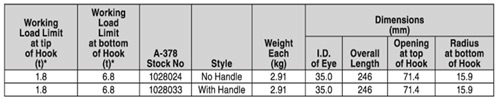

A-378 Sorting hook

• Forged alloy steel-Quenched and Tempered.

• Deep straight throat permits efficient handling of flat plates or large cylindrical shapes.

S377 Barrel Hooks

• Forged carbon steel –Quenched tempered.

• Meet the performance requirements of federal specification RR-C-271F,Type V, class 6,except for those provisions of the contractors.

LINKS

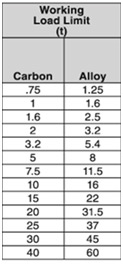

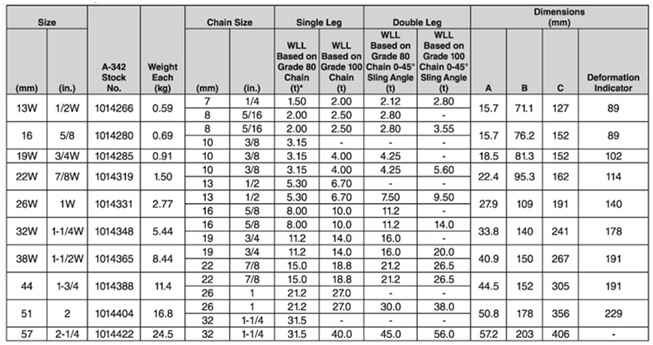

ALLOY MASTER LINKS

Rating below is for use with Chain slings fabricated in accordance with EN 818-4.

• Alloy Steel – Quenched and Tempered.

• Individually Proof Tested With Certification.

• Proof tested with 60% inside width special fixtures sized to prevent localized point loading per ASTM A-952.

• Meets or exceed all requirements of ASME B30.26 Including Identification, Ductility, Design Factor, Proof Load and temperature requirements. Importantly, these links meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

• Forgings have a product identification code (PIC) for material traceability, along with the size, the name Crosby and USA in raised lettering.

• Selected sizes designated with”w” in the size column have enlarged inside dimensions to allow additional room for sling hardware crane hook.

• Incorporates patented QUIC-CHECK® Deformation indicators.

342 ALLOY MASTER LINKS

*Chain slings require that the Minimum Ultimate load be 4times the working load limit.

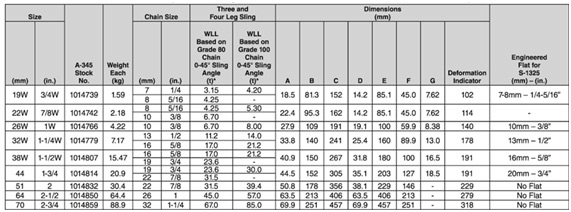

ALLOY MASTER LINK ASSEMBLY

A-345 MASTER LINK ASSEMBLY WITH ENGINEERED FLAT FOR USE WITH S- 1325A COUPLER LINK

*Chain slings require that the Minimum Ultimate load be 4times the working load limit

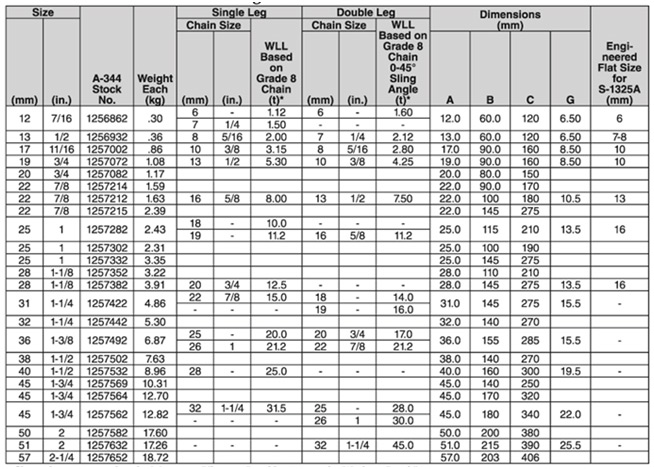

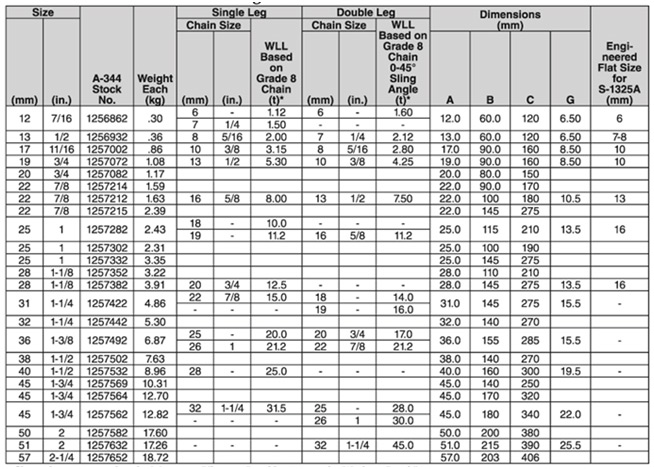

A-344 Welded Master Link with Engineered flat

Ratings below are for use with chain slings fabricated in accordance with EN 818-4.

• Alloy Steel – Quenched and Tempered.

• Individually Proof Tested With Certification.

• Proof tested with 60% inside width special fixtures sized to prevent localized point loading per ASTM A-952.

• Meets or exceed all requirements of ASME B30.26 Including Identification, Ductility, Design Factor, Proof Load and temperature requirements. Importantly, these links meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

• Meets the performance requirements of EN 1677-4:2001.

• Each link has a product identification code (PIC) for material traceability, along with the size and the name Crosby® or “CG” .

• Large Inside Width And Length To Allow Additional Room For Sling Hardware And Crane Hook.

• Engineered Flat For Use With S-1325a Coupler Link.

* Chain slings require that the Minimum Ultimate load be 4times the working load limit.

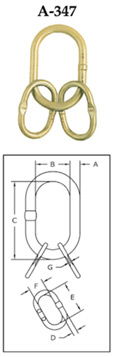

A-347 Welded Master Link Assembly With Engineered Flat