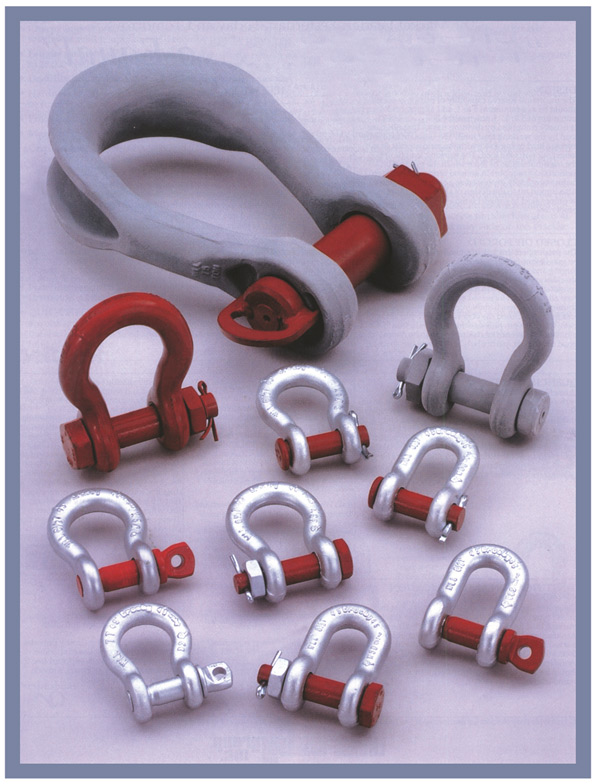

• Capacities 1/3 thru 55 metric tons.

• Forged-Quenched and Tempered, with alloy pins.

• Working load limit permanently shown on every shackle.

• Hot dip galvanized or self colored.

• Fatigue rated.

• Shackle 25t and larger are RFID EQUIPPED.

• Shackles can be furnished & proof tested with certificates to designated standards,

Such as ABS, DNV, LIoyds or other certification. Charges for proof testing and certification available when requested at the time of order.

• Shackles are quenched and tempered and can meet DNV impact requirements of 42 joules (31 ft. lbs.) at -20 degree Celsius (-4 degree F).

• Sizes 1/2t-25t meets the performance requirements of EN 13889:2003.

• Meets or exceeds all the requirements of ASME B 30.9.

• Type approval and certification in accordance with ABS 2006 steel Vessel Rules 1-1-17.7, and ABS Guide for Certification of Cranes.

• Crosby has type approved to provide 2t through 25t 209 anchor shackles that meets the requirements of DNV certification notes 2.7-1 – Offshore containers. These Crosby shackles (met by our current standard products) are: statistical proof test of 1% to 3%, based on lot size is required. Impact test of shackle bow and pin are provided. The tests are conducted by Crosby and we provide 3.1 test certificates upon request with results.

• Look for the Red Pin®….. the mark of genuine Crosby quality.

• Capacities 1/3 thru 150 metric tons.

• Working load limit permanently shown on every shackle.

• Forged-Quenched and tempered, with alloy pins.

• Hot dip galvanized or self colored

• Fatigue rated (1/3t – 55t).

• Shackles 25t and larger are RFID EQUIPPED.

• 2t through 25t bow and bolt are certified to meet charpy impact testing of 42 joules (31 ft lbs) min. average at -20 degree C (-4 degree F).

• Meets or exceeds all the requirements of ASME B 30.9.

• Sizes 1/2t-25t meets the performance requirements of EN 13889:2003.

• Shackles 55 metric tons and smaller can be furnished & proof tested with certificates to designated standards, Such as ABS, DNV, LIoyds or other certification when requested at the time of order.

• Shackles 85 metric tons and larger can be provided as follows.

• Serialized Pin and Bow • Magnetic Particle Inspected

• Material Certification (chemical) • Certification must be requested

at the time of order

• Type approval and certification in accordance with ABS 2006 steel Vessel Rules 1-1-17.7, and ABS Guide for Certification of Cranes.

• Crosby 2t through 25t G2130 anchor shackles are type approved to DNV certification notes 2.7-1 – Offshore containers. These Crosby shackles are statistical proof & impact tested. The tests are conducted by Crosby and we provide 3.1 test certification is available upon request.

• Look for the Red Pin®….. the mark of genuine Crosby quality.

• Quenched and Tempered.

• Alloy bows, Alloy bolts.

• Forged alloy steel 30 thru 175 metric tons. Cast alloy steel 200 thru 400 metric tons.

• Working Load Limit is permanently shown on every shackle.

• Pins are galvanized and self colored.

• All sizes are RFID EQUIPPED.

• Shackles are Quenched and Tempered and can meet DNV impact requirements of 42 joules (31 ft lbs) at -20 degree C (-4 degree F).

• All sizes are individually proof tested to 2.0 times the working load limit.

• Shackles 200 metric tons and larger are provided as follows.

• Serialized Pin and Bow

• Material Certification (chemical)

• Magnetic Particle Inspected

• Certification must be requested at the time of order

• Meets or exceed all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these shackles meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

• Type approval and certification in accordance with ABS 2006 steel Vessel Rules 1-1-17.7, and ABS Guide for Certification of Cranes.

• Look for the Red Pin®….. the mark of genuine Crosby quality.

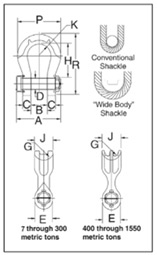

G-2160 / S-2160 “WIDE BODY” SHACKLES

• All sizes Quenched and Tempered for maximum strength.

• Forged alloy steel from 7 through 300 metric tons.

• Cast alloy steel from 400 through 1550 metric tons.

• Sizes 300 metric tons and smaller are proof tested to 2 times the working load limit.

• Sizes 400 metric tons and larger are tested to 1.33 times working load limit.

• All ratings are in metric tons, embossed on side of bow.

• G-2160, (7-55t), are Hot Dip Galvanized and pins are painted red.

• G-2160, (75t and larger), bows are furnished Dimetcoted, and pins are Dimetcoted, then painted red.

• S-2160 bows and pins are painted red.

• Shackles, 30t and larger are RFID EQUIPPED.

• Greatly improves the life of wire rope slings.

• Can be used to connect HIGH STRENGTH Synthetic webbing slings, HIGH STRENGTH Synthetic Round slings or Wire Rope slings.

• Increase in shackle bow radius provides minimum 58% gain in sling bearing surface and eliminates the need for a thimble.

• Increases usable sling strength minimum of 15%.

• Pin is non-rotating, with weld on handles for easier use (75t and larger).

• Bow and bolt are certified to meet charpy impact testing of 42 joules (31 ft lbs) min. average at -20 degree C (-4 degree F).

• All 2160 shackles are individually proof tested and magnetic particle inspected. Crosby certification available at time of order.

• Shackles requiring ABS, LIoyds and other certifications are available upon special request and must be specified at the time of order.

• Shackles 18t and larger have DNV Type Approval to Rules for Certification of Lifting Appliances, and are produced in accordance with DNV MSA requirements. Data book is provided that includes required documents.

• Serialization

• Material Testing (Physical/ Chemical/ Charpy).

• Proof testing

• Look for the Red Pin®….. the mark of genuine Crosby quality.